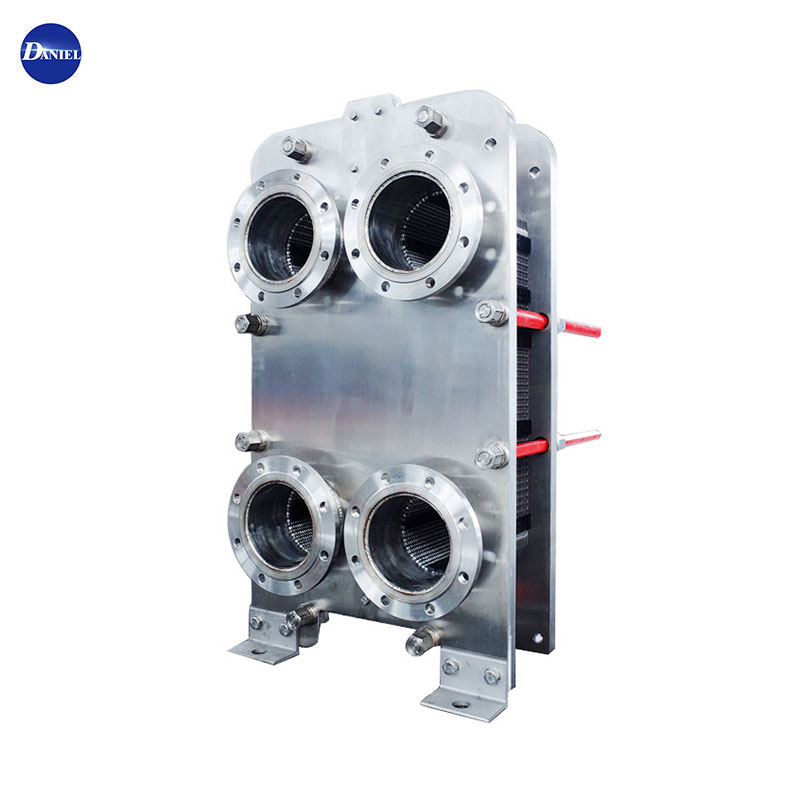

Plate Heat Exchanger

A plate heat exchanger is a type of heat exchanger that uses a series of corrugated metal plates to transfer heat between two fluid streams. It is a highly efficient and compact device commonly used in various industries for heating, cooling, and heat recovery applications.Here are the key component......

Send Inquiry

Product Description

A plate heat exchanger is a type of heat exchanger that uses a series of corrugated metal plates to transfer heat between two fluid streams. It is a highly efficient and compact device commonly used in various industries for heating, cooling, and heat recovery applications.

Here are the key components and working principles of a plate heat exchanger:

1. Plates: The heart of a plate heat exchanger consists of multiple plates arranged in a stack. The plates are typically made of stainless steel or other corrosion-resistant materials. They have corrugations or ridges on their surfaces, which create turbulence and increase the heat transfer area.

2. Frame: The plates are held together in a frame, which provides structural support and facilitates the flow of the fluids through the heat exchanger.

3. Fluid Channels: The plates have alternating channels for the two fluid streams. The hot fluid flows through one set of channels, while the cold fluid flows through the adjacent channels. This arrangement allows for efficient heat transfer between the fluids.

4. Gaskets: Gaskets are placed between the plates to create a sealed flow path for each fluid and to prevent mixing of the two streams. The gaskets also ensure proper alignment and sealing of the plates.

5. Inlet and Outlet Ports: The heat exchanger has inlet and outlet ports for each fluid stream. The fluids enter the heat exchanger through the inlet ports, flow through the respective channels, and exit through the outlet ports.

The operation of a plate heat exchanger involves the following steps:

1. Fluid Flow: The hot and cold fluids enter the heat exchanger through their respective inlet ports and flow through the channels created by the plates. As the fluids pass through the channels, heat is transferred from the hot fluid to the cold fluid through the metal plates.

2. Heat Transfer: The corrugations on the plates create turbulence, promoting efficient heat transfer between the fluids. The large surface area of the plates allows for a significant heat exchange, making plate heat exchangers highly efficient.

3. Counterflow or Parallel Flow: Depending on the design and application, the fluids can flow in either a counterflow or parallel flow arrangement. In a counterflow configuration, the hot and cold fluids flow in opposite directions, maximizing the temperature difference and heat transfer. In a parallel flow configuration, the fluids flow in the same direction, which may be advantageous for specific applications.

4. Exit of Fluids: After the heat exchange, the fluids exit the heat exchanger through their respective outlet ports. The hot fluid is cooled, while the cold fluid is heated.

Plate heat exchangers offer several advantages, including high heat transfer efficiency, compact size, easy maintenance, and the ability to handle high-pressure and high-temperature applications. They are used in various industries, such as HVAC systems, refrigeration, power generation, chemical processing, food and beverage, and many others, where efficient heat transfer is required.